Compatible with the Laser Direct Structuring (LDS) technology of German company LPKF, enabling circuits to be formed on the surface of injection-molded articles

LPKF-LDS Technological Features

- Possible to form circuits on structural components, allowing for a high degree of design freedom

- Can be applied to small curved surfaces and thin-walled molded articles, allowing for downsizing and weight reduction of articles

- Circuit design and position can be changed at will in a short time

- Reduced costs thanks to fewer manufacturing processes and shorter assembly time

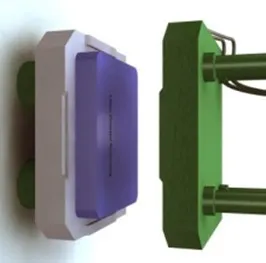

LPKF-LDS Process

-

1. Injection molding of LDS-compatible resin (existing molds can be used)

-

2. Activation of irradiated area using LPKF laser (determining electrically conductive pattern design)

-

3. Electroless copper plating

(conductor pattern formation) of laser-irradiated area