Concept

In recent years, electronic devices have become more sophisticated and functionally complex. The amount of signals they handle and the processing speed for these signals have increased, resulting in additional heat being generated by electronic components.

Moreover, as devices become smaller and more portable, it has become more essential than ever to manage heat while reducing their weight.

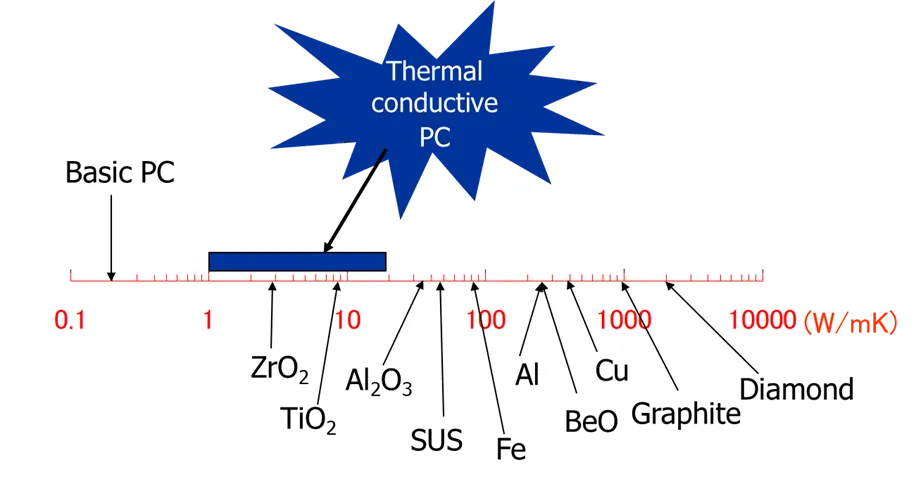

Thus, there is a growing demand for anti-heat measures by using thermally conductive resins for components that were conventionally made of resins.

Given the situation, Mitsubishi Engineering-Plastics Corporation has developed thermally conductive resins with a relatively low specific gravity. Using these thermally conductive resins can:

- Prevent local temperature rises in equipment, thus preventing operational defects

- Allow for lighter parts compared to metal

- Allow for greater design flexibility compared to metal die casting

- Enable heat-dissipating parts to be integrated, thus reducing the number of parts as well as the cost among other benefits.